23rd Wing Public Affairs

11/10/2008 - MOODY AIR FORCE BASE, Ga. -- Approximately five members of a depot maintenance team arrived at Moody Nov. 12 and provided A-10C Thunderbolt II maintainers hands-on training to perform major crack repairs on the aircraft.

The team came from Ogden Air Logistics Center at Hill Air Force Base, Utah, where all C-130 Hercules aircraft, A-10s and F-16 Fighting Falcons go for maintenance. The depot team performs extensive and heavy maintenance that cannot be done at the unit level.

"The goal of the depot team was to teach maintainers how to repair major cracks so that grounded A-10s can be returned to flying status," said Master Sgt. Jeffrey Andrews, 23rd Equipment Maintenance Squadron repair and reclamation section chief. "Each depot team member had an A-10 to repair so they could show how major repairs are done and allow Airmen to apply what they learned."

Moody has more than 10 A-10s that have to be repaired and returned to flying status, said Sergeant Andrews.

In addition to Moody maintainers, there were 40 active duty, Reserve and Guard maintainers from several bases including Davis-Monthan Air Force Base, Ariz., Nellis AFB, Nev., Whiteman AFB, Mo., and Willow Grove Air Reserve Station, Pa., who received training to bring back to their bases.

All the A-10 maintainers comprised of five different Air Force specialties to include repair and reclamation, metals technology, sheet metal technology, nondestructive inspection and crew chiefs.

"It would cost too much to fly all the aircraft to Hill," said Master Sgt. Steve Grimes, Air Combat Command Headquarters A-10 maintenance liaison. "It would also take longer to repair all since three could only be sent at a time. This method is more cost-effective and it would be a faster way to repair the A-10s."

The Ogden Air Logistics Center has responsibilities for Air Force-wide item management, depot-level overhaul and repair for all types of landing gear, wheels, brakes and tires and is the logistics manager for all conventional air munitions, solid propellants and explosive devices used throughout the Air Force. The center is the Air Force technical repair center for composites.

The team concentrated on teaching trunnion removal and sheet metal repair. The trunnion is the attachment point of the main landing gear and wing, which receives stress that causes cracks.

"The whole process has been surprisingly effective and swift," said Sergeant Andrews. "Although, there is no definite time of when all grounded A-10s will be fixed, the newly-trained maintainers have the proper training to immediately start teaching and repairing their own A-10s.

"We want the A-10s to be properly repaired as soon as possible so that they are mission-capable in support of the Global War on Terrorism," he added.

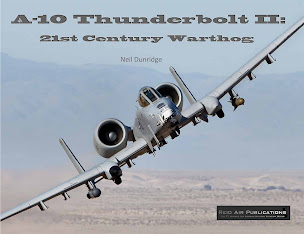

Forty Airmen from eight bases begin the task of simultaneously preparing five A-10C models for wing section repair at Moody AFB on November 7, 2008. Visible in the foreground is A-10 79-0159 from the 75th Fighter Squadron. Airmen not assigned to Moody will learn how to repair the A-10C wing section and return home station to share this knowledge within their units. In order to accomplish these repairs, Airmen must climb into tiny compartments within the wing to reach certain areas. (U.S. Air Force photo by Senior Airman Javier Cruz) Hi-res

Source

No comments:

Post a Comment